Additive Manufacturing of

Prototypes and End-Use Parts

Rapid 3D provides a full spectrum of 3D printing, 3D Scanning, and Reverse Engineering solutions for the

highest-quality prototyping and low-volume production.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS)

SLS 3D Printing is a powder bed fusion process that uses real thermoplastic (Nylon PA12) materials to produce parts that are perfect for end-use parts.

Production items made using our In-house EOS selective laser sintering machine are durable, heat resistant, and repeatable. As a result, a variety of industries, including automotive, textile, general engineering, medical etc., get benefited by incorporating this technology into their development process

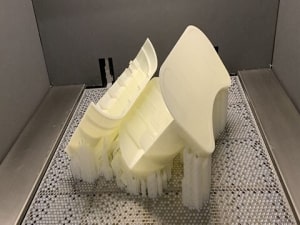

Stereolithography (SLA)

Stereolithography (SLA)

Stereolithography technology works by curing resin materials layer-by-layer through the exposition to UV light. One of the biggest advantages of SLA is the dimensional accuracy and small intricate details. The surface finish is very good, which means the technology is well suited for visual models and details where the parts are aesthetically appealing.SLA is a versatile and reliable 3D printing technology Bangalore that offers fast, high-quality results for a range of applications.

Fused Deposit Modeling (FDM)

Fused Deposit Modeling (FDM)

FDM works by extruding the melted material through the print nozzle. The material hardens as it gets layered. FDM 3D printing creates strong and durable parts out of most industrial-grade thermoplastics. It is widely used for prototypes, final products, and concept models and became a popular approach in various industries, including architecture, engineering, construction, archaeology, and more, as it offers increased accuracy and efficiency compared to traditional methods.

3D Scanning & Reverse engineering

3D Scanning & Reverse engineering

Rapid 3d offers scanning services through a GOM – Blue light Scanners & White light scanners, in order to deliver accurate 3D scan outputs. 3D scanning services can be a valuable time and cost saver, when you need reverse engineering designs or when you need to compare a fabricated part to the original CAD (Computer Aided Design) rendering. 3D scanning tolerances are typically between 30 and 50 microns.

Our Robust Capabilities Behind The Numbers

Over 7 years of experience

With more than 7 years of experience, we at Rapid 3d are experts in Rapid Prototyping Services and Additive Manufacturing Technologies.

300+

Companies Served

150,000+

Unique Parts Produced

3+

Countries Shipped

5000+

Unique parts scanned

7+

Years in Business

Satisfaction guarantee

Our experts design the product to perfection as per your requirements. Our top priorities are your pleasure and the quality of your prototypes.

Are you a Startup or New product development team?

✨You’ve got a wonderful product concept and want to be the first to market with it, but injection moulding tooling requires a significant upfront expenditure, and the design is still being worked on.

✨We can relate to that problem because, prior to employing additive manufacturing, we faced a similar one.

Rapid 3D – Leading 3D

Printing Service Company

in Bangalore

Using our 3D Printing technology in Bangalore we can supply the initial production runs of your components so you can test and refine products before committing to tooling.

No Tooling Capex

A new product on the market requires a significant investment in injection moulding tooling. With the SLS 3D printing technique parts size of 100 – 500 nos can be easily produced economically and in a short period of time & without any need for tooling.

Design Freedom

Component design for SLS serial production has far fewer design constraints than injection moulding, CNC or other processes:

Go to market faster

The major benefit of 3D printing in Bangalore is that parts can be realized in 1-2 days’ time. Iterate your designs, validate your product and pilot launch your product to get the first mover advantage.

Continual Improvements

No matter how many times you test a product, there is always room for enhancements that aren’t discovered until the product is on the market.

With 3D the component’s design can be improved upon or modified entirely without having to modify expensive and time-consuming tooling or scrap the mold.

Low Inventory

Parts can be ordered in small batches or JIT without the need for tooling. Small batches of 10 -100 units can be made in just 3-5 days’ time, saving money on inventory upfront.

On-Demand

Perhaps you just require a few extra components, instead of having to order 1000s we can produce as few as you need.

Or you’ve just received a big order, there’s no need to wait for an available injection moulding press when we can produce thousands of components in a matter of days.

Variants and customization

As consumers increasingly tend to value the importance of being recognized as unique, how can standard products be designed to fit individual needs!

Our 3D printing company in Bangalore does not require any molds or specific tools that are normally needed for traditional manufacturing methods. With the set-up of the right digital tools, the customization choices that customers make can be implemented within the 3D file straight away, and then go to production.

START WORKING WITH EXPERTS

YOU CAN TRUST

Rapid 3d provide a full spectrum of end-to-end digital manufacturing solutions that leverage Additive manufacturing, 3D Scanning, Metrology & Reverse engineering. We empower companies to reduce the product development cycle, enhance prototyping capabilities, improve production efficiency and maximize supply chain flexibility.

Established in 2017 we are committed to providing extraordinary service and craftsmanship with the ideal manufacturing experience to fit your specific need, every time. We have worked together with our customers to reinvent the way they produce jigs and fixtures, and prototypes, and help to leverage low-volume production and on-demand inventory.

For more than 6 years, we have been providing industrial-grade 3D printing services, Batch Production, and Low-volume production services to empower companies to speed up their product development cycle. We focus on bringing your ideas to life faster than you thought possible using the best in Additive and Digital Manufacturing technologies.

Capabilities include SLS (Selective Laser Sintering) by EOS Germany, SLA (Stereolithography) models, and FDM (Fused Deposition Modeling) prototypes in engineering-grade thermoplastics.

SUPPORT WITH HUMAN TOUCH

We don’t believe in the DIY platform that will keep you waiting for assistance when you need it. Even though we’re great fans of automation and self-service, nothing can match the effectiveness and efficiency of speaking with a real professional in person to discuss the specifics of your project.

The Widest Range of 3D Printing Materials and Technologies

Are you looking for different 3D printing technology in Bangalore?

Rapid3D is a leading 3D printing company in Bangalore that specializes in providing exceptional 3D printing solutions. We utilize cutting-edge technology and a team of skilled professionals to cater to various industries and applications. Our services include creating product samples, manufacturing end-use parts, and producing prototypes that meet your specific needs.

We offer a diverse range of 3D printing materials Bangalore, such as plastics, metals, ceramics, and composites, to fulfill your specific requirements. These materials are utilized for various applications, ranging from product development and prototyping to producing final products and end-use parts. Our company’s expertise in materials enables us to provide clients with the best options based on their project needs.

ABOUT RAPID 3D

INDUSTRIES WE SERVE OUR 3D PRINTING SERVICES IN BANGALORE

PRINT FOR YOUR LIFE AND LOVE WHAT YOU MAKE WITH OUR 3D PRINTERS.

Aerospace

Medical

Architecture

Customized gifts

Automotive

Education

Electronic

Casting

TRUSTED BY

Frequently Asked Questions

Contact Us