AEROSPACE

The aerospace industry was one of the earliest users of 3D printing and is a major contributor in the development of this technology for both manufacturing end-use parts and prototyping. Airlines depend on 3D printing to minimize warehouse space limits, decrease waste from conventional production techniques, and reduce supply chain constraints. Large amounts of time, money, and space are saved when airplane parts are quickly produced on demand.

Airbus, now has a record number of 3D printed parts on their new A350 XWB aircraft, with 1,000+ parts.

ARCHITECTURE

Architecture 3D printing is revolutionizing the construction industry. This cutting-edge technology allows architects and builders to turn intricate designs into tangible structures with unprecedented precision. It reduces construction time and costs, while also offering limitless creative possibilities. Whether it’s creating innovative facades, sustainable structures, or custom components, 3D printing is shaping the future of architecture. Embrace the future of design and construction with this transformative technology.

AUTOMOTIVE

Automotive 3D printing is driving the future of the automotive industry. This groundbreaking technology enables the production of lightweight, high-performance components, reducing vehicle weight and improving fuel efficiency. It also allows for rapid prototyping, custom parts, and streamlined supply chains. From concept to production, 3D printing is accelerating innovation and enabling the creation of safer, more efficient vehicles. Embrace automotive 3D printing to stay at the forefront of the automotive evolution.

CUSTOMIZED GIFTS

Customized gifts through 3D printing offer a truly personalized touch to your celebrations. With this technology, you can transform ideas into unique, one-of-a-kind gifts. From personalized figurines and jewelry to bespoke home décor, 3D printing lets you create meaningful presents that reflect your sentiment. Say goodbye to generic gifts and embrace the creativity and sentimental value that come with custom 3D-printed gifts, making your occasions extra special.

EDUCATION

Technology and education go hand in hand and if they are used together they can compliment each other spectacularly.

Education 3D printing is reshaping the learning experience. This innovative technology empowers students to bring their ideas to life by designing, prototyping, and fabricating objects in the classroom. It fosters creativity, problem-solving, and hands-on learning, bridging the gap between theory and practice. Whether it’s science, engineering, or art, 3D printing in education enhances understanding and encourages exploration, preparing students for the challenges of the future. Embrace this educational revolution to inspire the next generation of innovators.

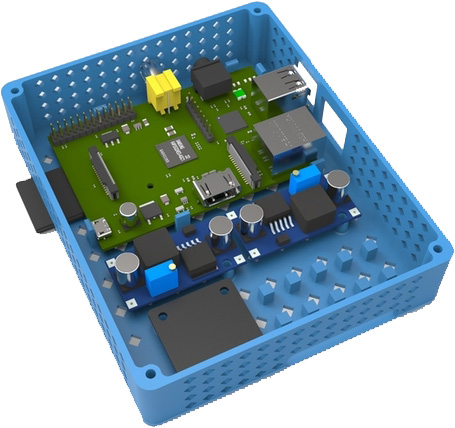

ELECTRONICS

Electronics 3D printing is driving a technological transformation. This cutting-edge method enables the creation of intricate and customized electronic components, revolutionizing the design and manufacturing processes. It allows for compact, lightweight, and efficient devices, from wearables to advanced sensors. With this technology, rapid prototyping and innovation become more accessible, speeding up product development and reducing waste. Embrace electronics 3D printing to reshape the future of electronics and bring unprecedented versatility to the industry.

CASTING

Casting 3D printing merges traditional craftsmanship with modern technology. It facilitates the production of complex and intricately designed molds, patterns, and prototypes for metal, ceramic, and plastic casting processes. This innovative approach offers precision, speed, and cost-effectiveness, making it a game-changer in the casting industry. Whether creating intricate jewelry, precision-engineered parts, or artistic sculptures, casting 3D printing enables exceptional detail and quality. Embrace this revolution in casting to expand your design possibilities and streamline production.

In terms of overall costs, 3D printing is always the more economical alternative to conventional processes up to a certain batch size, since tool costs are eliminated.

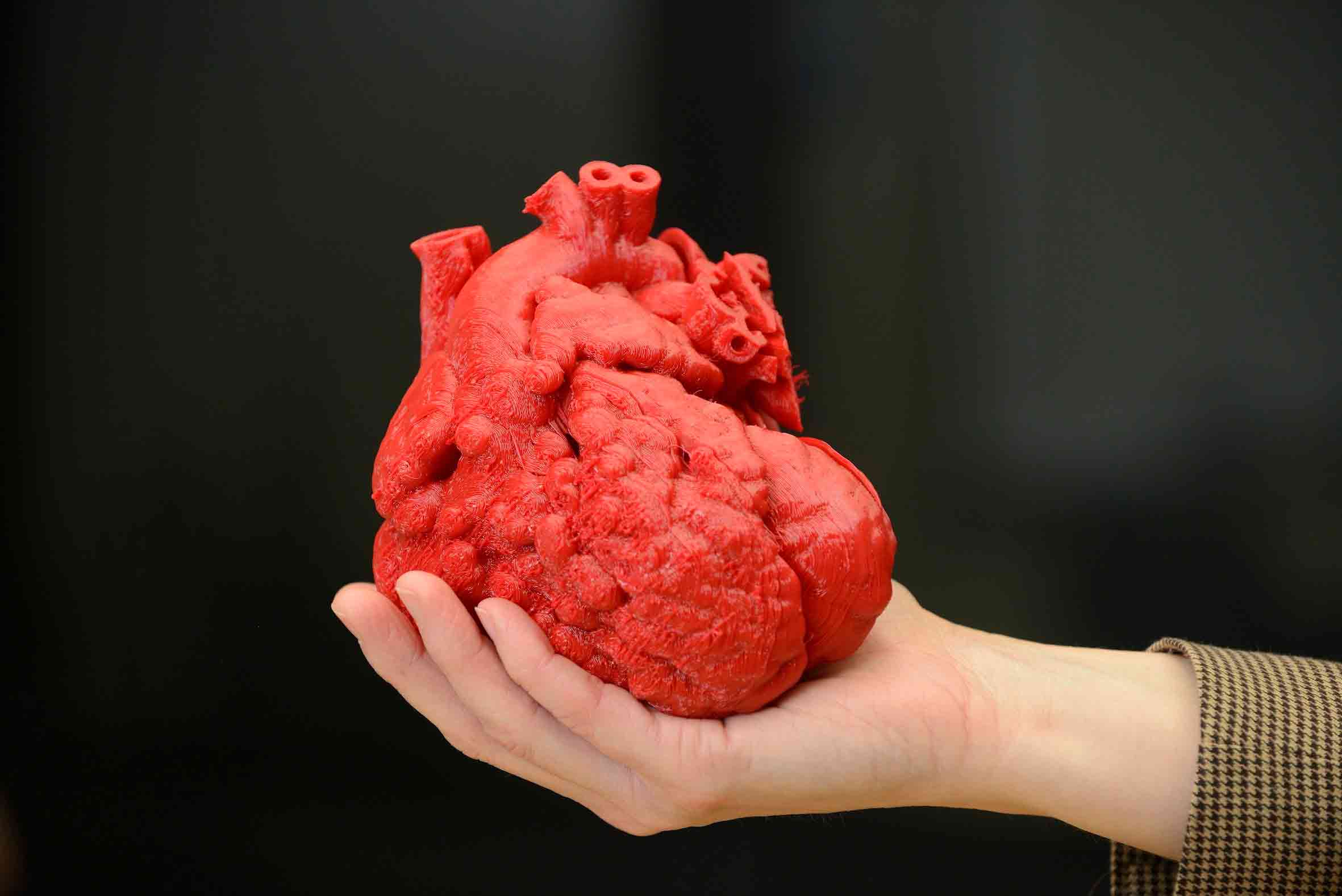

MEDICAL

Medical uses for 3D printing, both actual and potential, can be organized into several broad categories, including tissue and organ fabrication, the creation of customized prosthetics, implants, and anatomical models, and pharmaceutical research regarding drug dosage forms, delivery, and discovery. The application of 3D printing in medicine can provide many benefits, including: the customization and personalization of medical products, drugs, and equipment; cost-effectiveness; increased productivity; the democratization of design and manufacturing; and enhanced collaboration.

A doctor can look at and practice on a customized 3D printed model prior to surgery. Then we potentially have a better surgical outcome.