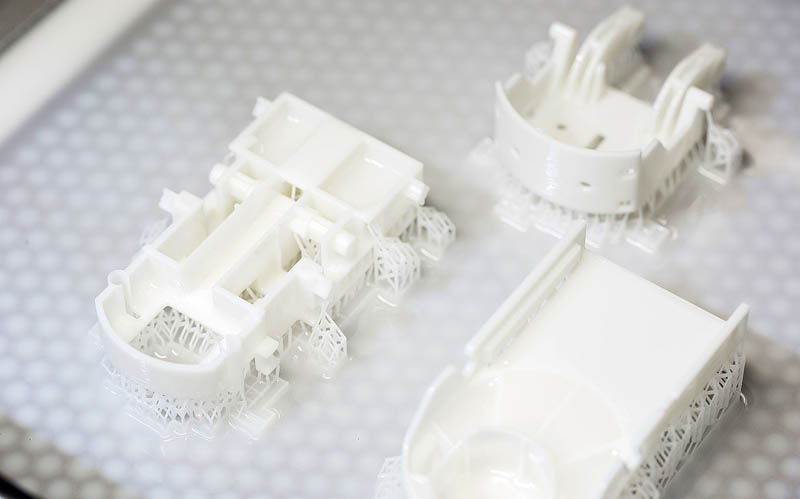

Stereolithography (SLA) is an additive manufacturing process that belongs to the Vat Photopolymerization family. In SLA, an object is created by selectively curing a polymer resin layer-by-layer using an ultraviolet (UV) laser beam. The materials used in SLA are photosensitive polymers that come in a liquid form.

Why Choose SLA for your 3D Printing Project?

SLA is a great option for rapid prototyping and project ideas that require for the production of extremely precise and minutely detailed parts. It’s ideal for producing show-and-tell parts to enable validation of concept ideas and ergonomic testing.

SLA capabilities

| Requirement | Specification |

|---|---|

| Maximum build Volume (Single Build) | 600 x 600 x 400 mm (Parts shall be split, Print separately and fused together to form much larger volumes) |

| Standard lead time | 4-5 business days |

| Dimensional accuracy | ± 0.2 mm |

| Layer height | 50 -100 μm |

| Finish | Very smooth surface finish |