SLS 3D Printing Services in Chennai & Coimbatore

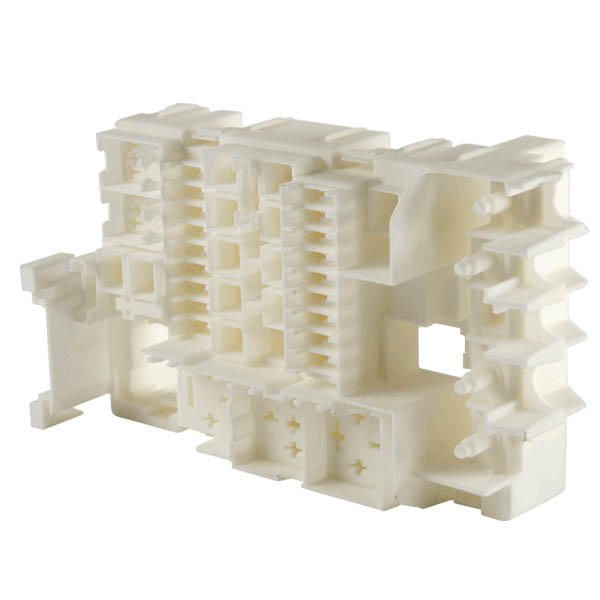

Rapid 3D’s SLS 3D printing technique fuses plastic powder particles together with a laser to build parts layer by layer. This powder bed technology rivals injection moulding strength and mechanical properties for short production runs of parts. SLS technology in 3D Printing Services has hardly any printing limitations, giving freedom to design and print complex geometries.

SLS is a powder bed fusion 3D printing technology. It uses a CO2 laser to fuse tiny bits of nylon powder, tracing the geometry of digitally sliced CAD models layer by layer, after which a re-coater deposits a new layer of powder and the build platform moves down one layer in height. The process is then repeated until the parts are complete.

How does SLS 3D printing works

In Coimbatore and Chennai, a Rapid 3D service provider offers cost-effective SLS 3D printing, an additive manufacturing technology that utilizes a high-powered laser to fuse tiny polymer powder particles into a solid structure based on a 3D model. This process delivers high-quality results at an affordable price.

Printing

In SLS 3D Printing, a laser selectively sinters particles of a polymer powder, fusing them together and building a part layer by layer. The materials used in SLS 3D printing are thermoplastic polymers that come in a granular form.

Cooling

After printing, the build chambers need to slightly cool down inside the print enclosure and then outside the printer to ensure optimal mechanical properties and avoid warping in parts. This can take a significant amount of time.

Post processing

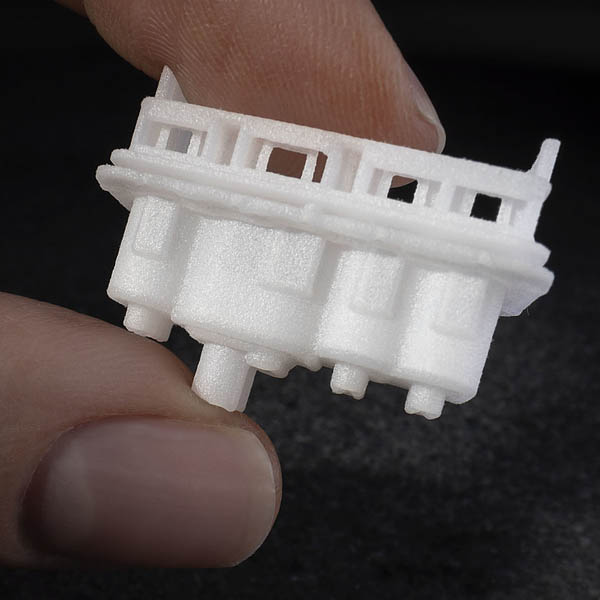

The finished parts need to be removed from the build chamber, separated, and cleaned of excess powder. The powder can be recycled, and the printed parts can be further post-processed by media blasting or media tumbling.

Materials

The most common material for selective laser sintering is nylon, a highly capable engineering thermoplastic for both functional prototyping and end-use production.

SLS capabilities

| Requirement | Specification |

|---|---|

| Maximum build Volume (Single Build) | 340 x 340 x 600 mm (Parts shall be split, Print separately and fused together to form much larger volumes) |

| Standard lead time | 4-5 business days |

| Dimensional accuracy | ± 0.2 mm |

| Layer height | 100 μm |

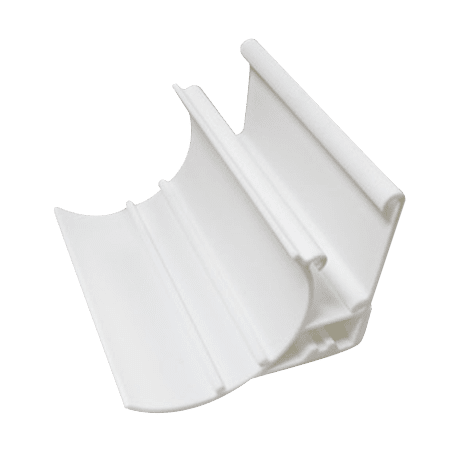

| Finish | As printed SLS parts are typically white or stone grey in color with a smooth surface and a powder texture and without visible layers |

Applications of SLS (Selective Laser Sintering) 3D printing